Every time a vehicle is up on one of our lifts, whether it would be for an oil change, brake job, etc; it goes throughout an inspection of every component that is visible to an automotive technician’s eye & ear:

-

Technical appearance of brake parts & components

-

Noise & vibrations in suspension mechanisms

-

Excessive noise in engine & transmission

-

Engine components belt wear

-

Operational testing of battery, alternator & starter

-

Fluid check & top off

-

Check for oil leaks

-

Tire wear

A certain pattern within a tire wear can tell us a lot about the vehicle suspension & alignment components. A wavy wear when looking from a side of a tire may result in bad shock absorbers or wheel misbalance. Feather edge wear when looking from the front shows the possibility of a necessary wheel alignment.

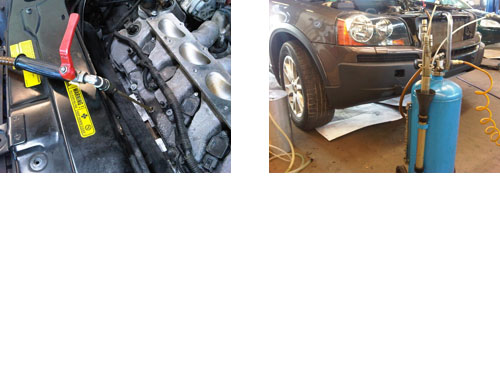

On upper class vehicles, during oil changes the motor oil is drained with help of dynamic air vacuum pump, which deliberately drains out the oil more fluently rather than traditional unscrew-the-oil-pan-plug method.

English

English  Русский

Русский  Українська

Українська